Project Aratu: yet another 3dof hexapod

June 24, 2023

Tags: robotics project aratuI once read something along the lines of "some people can only live they childhood dreams after they become adults". Well, child me really liked robots and wanted to build some. Of course at the time I didn't have the know-how nor the resources required. Heck, much of the technology available today didn't even exist back then or wasn't available commercialy at a developing country like Brazil. Now, a lot has changed. We have microcontrollers 10x faster than computers were back then, and they are wide available worldwide (when there isn't a chip shortage going on anyways). I am also fortunate enough to be able to afford to build a relativelly complex robot, and more importantly I have developed all the skills and meta skills.

All projects need a name. Given that the project itself is a 6 legged robot, taking inspiration from nature is an obvious step. I wanted something that was a reference to something Brazilian, while being memorable in both Portuguese and English. After some research, I settled on "Aratu", which is a crab found from the south of Brazil up to Florida. It is found both in the pacific and atlatic coasts. Although crabs are decapods, while my project is an Hexapod, I decided to go with it. Most 6 legged insects I found didn't meet the "being memorable" criteria.

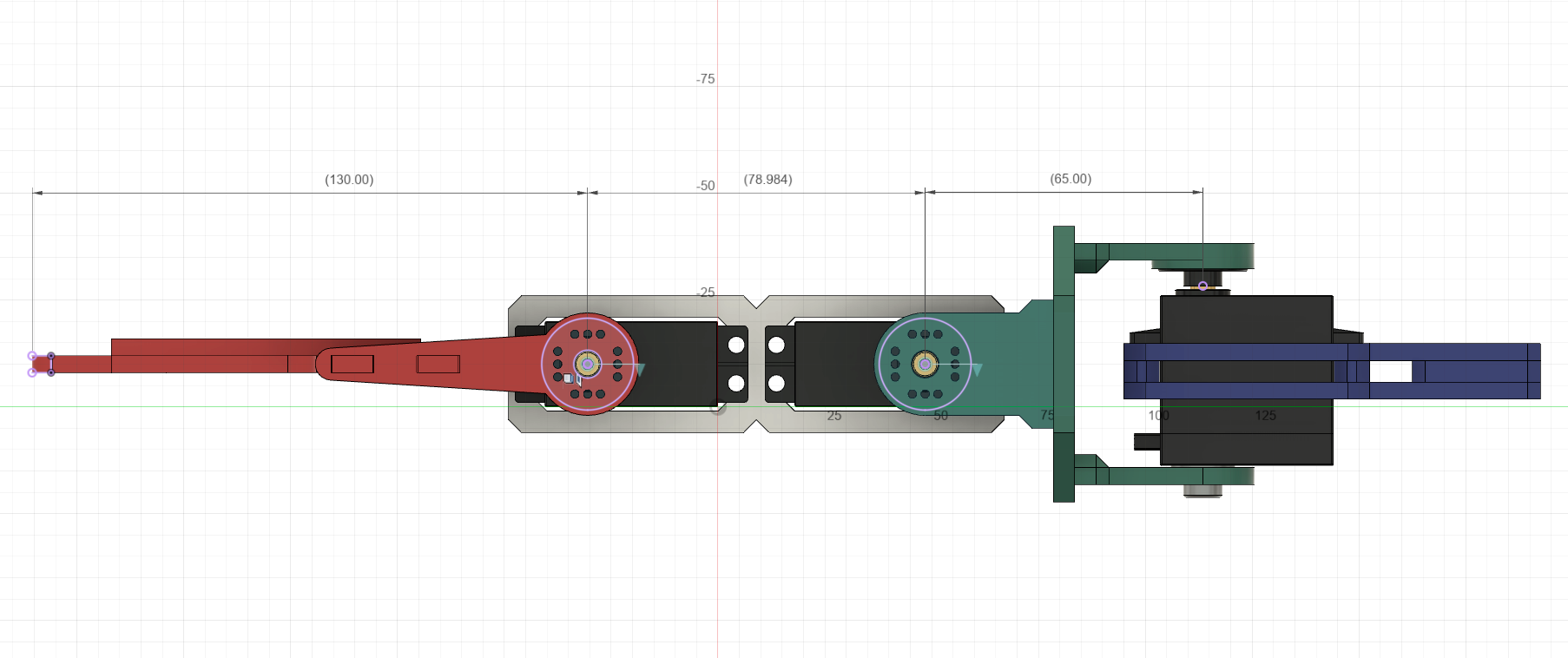

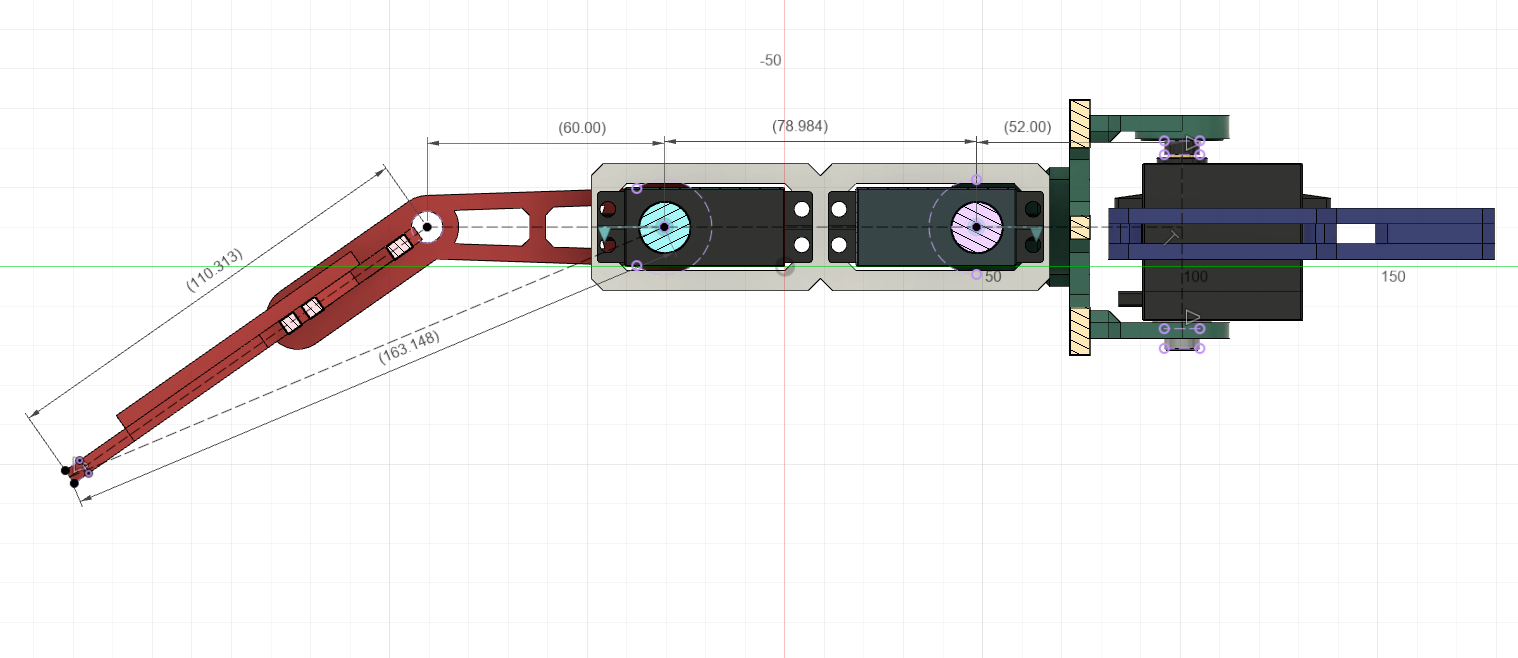

Considering that relativelly little experience with robotics and I am not much the research first kind of person, one priority was to be able to iterate, fail and recover fast. I found that I am often more productive when I go ahead and just try to make things and go as far as I can without losing momentum. Once I hit a blocker that I can't easily resolve, then I start researching on how to fix that particular problem. Rinse and repeat. The coxa and tibia bones were two such cases were the first designs failed, but I was able to fix them without having to change the other components. In the two next pictures, there are two different leg versions. In the first, the Tibia is straight and the Coxa has 65mm. In the second, the Tibia is longer and curved, allowing it to reach further down into the robot without required aggressive moves and the Coxa is shorter, reducing the strain on the main joint and improving rigidity. For the Tibia redesign, two side plates were updated, while the feet portion was reutilized. For the Coxa, the main piece connecting the two servos was also reutilized. This helped reduce the design and printing times allowing for a much faster iteration. Another point where this was helpful was in how the robot body was implemented having a grid of holes spaces 10mm apart, allowing attaching things that I didn't forsee without having to print new parts. For example when fixing different boards and cables.

During prototyping I took the first dev board I found, which happened to be an Arduino Uno R3. With it I was able to implement the Forward Kinematics routine, which is relatively straightforward. Even on the relatively weak 8bit AVR microcontroller running at 16MHz and without floating point arithmetic support the FK can be solved more than a thousand times per second. The Inverse Kinematics model isn't so simple though, and it can vary a lot if the leg model changes. Given my Optimization background, I decided to implement a numerical solution instead of an analytical one (keeping in sync with the modern software development approach of spending CPU time to save Engineering time). Having the IK be an optimization problem on top of the FK makes it much simpler to update the kinematics if/when the leg model changes.

The IK solver couldn't run fast enough even for a single leg, but with some tricks the situation improved. The solver uses a poor's man gradient descent (more like a greedy search), which can take advantage of previously found solutions as an starting point. Given that in 50 ms or so the leg can only move so far, the solver can start there and try to find the new updated position. This works very fast in most cases. Another simple optimizations can be used too, like having an acceptable error in the position. For cheap servos this is specially relevant, since having the exact angles down to 6 decimal places won't improve things if the servo can be a couple of degrees off from where it should be. Another way is to timeout the solver and return the best solution found so far, and on the next update continue from there. This helps with long moves where the movement is interpolated. This allowed the IK solved to run fast enough on the Uno for a single leg to validate the physical construction of the leg, the electronics and the code. In the video below, the leg can be seen moving the foot in a triangular gait pattern. It jitters as lot, but it is caused mostly by the cheap servos which often overshoot the target position.

Despite the optimizations, it was very unlikely that the Uno would be able to keep up with 6 legs to control. This was quickly proven when I tried 3 legs. Time to upgrade. My choice was the Teensy 4.1, a very capable 32bits microcontroller having a cloc of 600 MHz, with floating point support and even branch prediction. It has more features that I could ever want. It is even superscalar, meaning that it can execute more than one instruction at the same time under ideal circumstances. A quick benchmark between the Uno and the Teensy had very impressive results. The Uno could do on average 1355 FK solves per second, while the teensy could do 1086956. About 800x faster. One funny bug happened due to the Teensy being too fast. To move at a constant speed, the IK has to run periodically, but since there are no real guarantees on how long it will take to run again, it needs to account for the time between updates. On the Uno, this was usually in the 5~50ms range. For the teensy, it would often be 0ms, causing it to not move at all. The Uno required timeouts to keep it responsible, while the Teensy required some breaks. Instead of using microseconds to time it, I opted for using a timer to ensure it wasn't updated too often.

As for the project goals, there is quite a lot. I like to thing of them in two phases. The first being a platform phase, and the second an applications phase. For the platform phase, it is all about making the robot work. Here we have things like being able to stand, walk forwards, walk in any direction. Adjust gaits, translate and rotate the body dynamically, etc. This is plety ambitious already considering my lack of experience with complex robotics projects. Then, there is the second phase. For applications, the robot will be used as a platform for something more applied. The main one here is making it navigate autonomously, possibly using a spindle-type Lidar. For this, the robot being an hexapod doesn't matter as much since it would be anything capable of moving.

These are goals for the project itself, but there are personal goals involved too. The first goal, as mentioned in the first paragraph, is simply about doing something that I always wanted since being a kid. Then, there is the challenge itself of handling all the complexities of the project, including the more hard-sciency things like programming, mechanical design and eletrocnics as well as the soft-skills aspects. Time management being one and consistently developing the project instead of the very common burst of enthusiasm and then dropping it to never work on it again.

The project is opensource. The main code running embedded on the robot is available at the github repository here. A secondary repository used to remote control the robot can be found here. Not the best code around, but overall should be easy to understand. Check another Aratu related projects on the on the Aratu Tag.

Well, this is it for now. A follow up post will come soon, with an actual robot doing robot things.